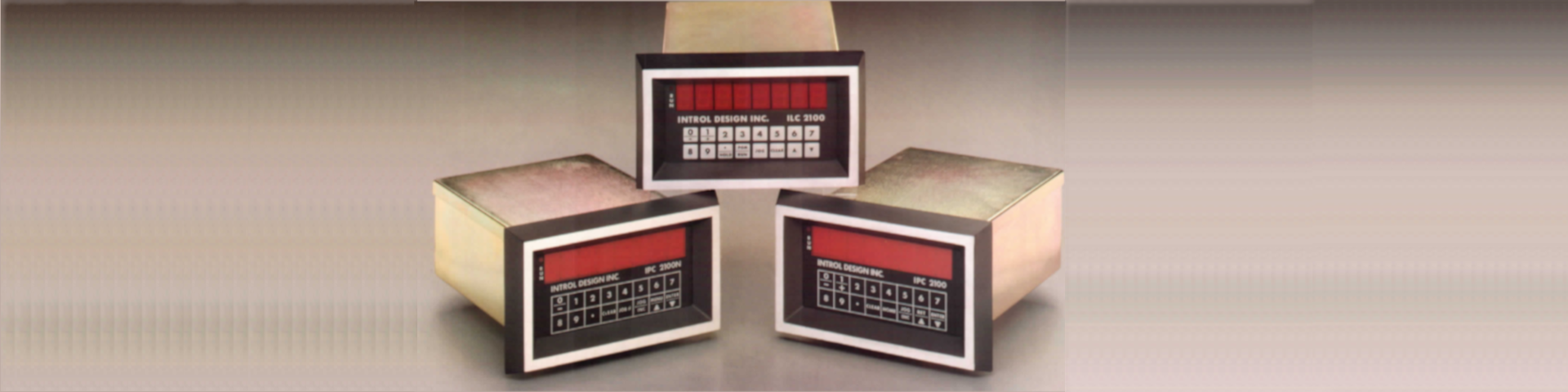

INTROL 2100

Series Motion Controllers

Incremental / Absolute Length / Postion

AC/DC Servo & Regenerative Drive or Steppers/Microsteppers

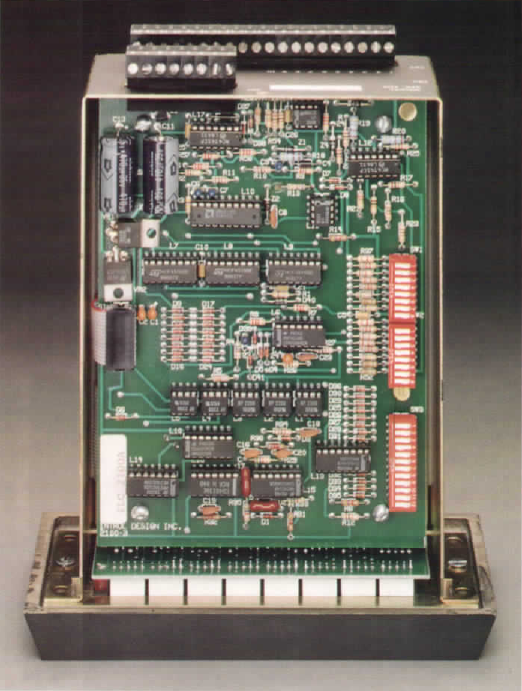

INTROL 2100 Series of Controllers are designed for a wide variety of motion control applications. Simplicity, accuracy and reliability are known facts to this family of controllers. Since the basic hardware of the mother device was proven in an industrial environment, many versions were designed based on the same original hardware with minor modifications and new software. This family offers 0 to± 10 VDC reference output to Servo/Regenerative Drives for closed loop applications or steps and direction output for Steppers and Microstepper Drives. All versions are capable of referencing (establishing HOME position) with excellent repeatability. In closed loop mode they can accept feedback frequency with up to 50 KHz external or 100 KHz internal after X2 logic. In open loop mode they can generate up to 500 KHz frequency which makes them adaptive to both Stepper and Microstepper drives. With Stepper/Microstepper Drives an incremental encoder could be used for Length/Position verification. An electronic tach option is available for each model to use with Regenerative Drives.

ILC’s

Many versions of the ILC have been developed. The original model is a 4 preset with batching. The later models have an active display. Some are designed with selectable registration indexing. All ILC’s are programmable on the fly and jumper selectable to follow external frequency (line speed) in continuous product flow applications. ILC’s have RS232 Serial communications with status reporting for process control. Although this group of controls is used for incremental indexing they can also be used in absolute type applications. The display can be Programmed to read in any unit of measurement with Auto Reset or External Reset to display each length or material usage. Since ILC's are designed for an indexing type application, they provide a programmable pause before inposition output is initiated. The inposition output is programmable to provide a timed one shot output.

IPC’S

This group of controllers are for absolute positioning using incremental encoder position feedback with Servo/Regenerative Drives or open loop with Steppers/Microsteppers. Some IPC’s are designed to follow commands through the RS422 Serial port for single and multi axis operation. Some are dual preset, teachable for pick and place type applications while others are more elaborate with a large data memory which can store up to 62 jobs, each up to 16 preset positions with batching and speed for milling type applications. Some others have the same job programming ability mentioned and also include a programmable antibacklash approach to the position. The latest version of the IPC has all the programming capabilities described above with a teach and PLC interface option. Some of the IPC’s also have programmable travel limits to avoid tool collision and will establish a reference point with the first position command after power up.

General Specification

- Input power: 115 VAC + 10%, 10VA, 50/60 Hz, jumper selectable 230 VAC fused.

- Encoder Power: On board 5 VDC + 5% at 150 ma. max.

- Operation: Closed loop with dual channel incremental encoder feedback or open loop.

- Length/Position: C6 Decade with decimal point in engineering units. (See ordering information for number of presets.)

- Speeds: Positioning speed, jog speed, home search speed and final approach speed.

- Calibrator: 6 Decade with decimal point. This is the number of pulses from encoder X2 or number of steps that measures to one unit of length.

- Position Counter: ± 8 Decade

- Feedback Input: Incremental dual channel quadrature type. Current sinking with pullups or TTL. 5 VDC to 24 VDC High level, 0 to 0.8 VDC Low level, 50 KHz max.

- Home/Reference Switch: Current sinking type. High level (not active) 5 VDC to 24 VDC max. Low level 0 volt to .8 VDC max.

- Control Inputs: Input functions vary based on model. JOG FWD, JOG REV, INCREMENT FWD, INCREMENT REV, RESET, HOME, SEQUENCE/INDEX. All inputs are current sinking edge and/or level sensitive. High level (not active) 5 VDC to 24 VDC. Low level (active) 0 VDC to 0.8 VDC.

- Analog Output: 0 to +10 VDC at 5 ma. optically isolated in digital section for drift free operation.

-

Discreet Output: Current sinking outputs up to 50 ma. at 24 VDC.

- Index complete output. On ILC’s programmable one shot. On IPC’S inposition output maintained.

- Batch complete output. (ILC’s only)

- Steps output selectable and programmable DC to 500 KHz, 50% duty cycle.

- Direction output

- Serial Interface: ILC’S, RS232. Some IPC’'S, RS422. Baud rate programmable 300, 600, 1200, 2400, and 4800. Full duplex, 8 data bits, one start bit and one stop bit.

- Display: 8 Decade .6” red LED modified alpha and numeric.

- Mechanical: Rugged zinc plated steel enclosure with cast aluminum bezel. Easy disconnectable terminal blocks and waterproof oil resistant keypad.

- Dimensions: 5.375” W x 3.00” H x 7.50” D. Bezel size 6.625” x 4.00”.

Ordering Information

-

Inrol Length controllers (Incremental)

- ILC2100 4 Preset length, 4 preset batch and RS232 Serial port.

- ILC2100A Same as above with active display.

- ILC2100B Same as ILC2100A - used with Steppers.

- ILC2100C Same as ILC2100A plus electronic tach output.

- ILC2100CG Same as ILC2100C with registration indexing option.

-

Introl Position Controllers (Absolute)

- IPC2100 Single preset with RS422 Serial port.

- IPC2100A Dual preset with teach mode.

- IPC2100N-1A 62 job, 16 preset position and 16 preset batch each job.

- IPC2100N-1D same as IPC2100N-1A plus speed presets.

- IPC2100N-1B Same as IPC2100N-1A - used with Steppers.

- IPC2100NCA Same as IPC2100N-1A plus electronic tach output.

- IPC2100ND Same as IPC2100N-1A plus teach mode and PLC interface.

- IPC2100NCD Same as IPC2100ND plus electronic tach option.

Quick Contact

If you have any questions or would like to book a session please contact us.